VIEN Group: Marine Industrial Solutions

Marine Industrial Solutions

At Vien Group LLC, we’re not just delivering services; we’re crafting experiences that merge high standards with innovation. Our mission is to revolutionize how value is delivered in our industry. We strive to be the architects of solutions that are not only economically savvy but also exceed the expectations of our customers in every project.

Marine Automatization and Control Services

About Marine Automatization and Control Services

At Vien Group, we are at the cutting edge of marine automation and control systems, providing solutions that enhance the operational efficiency, safety, and reliability of marine vessels. Our advanced automation technologies reduce the workload on crew members by automating routine tasks and offering comprehensive monitoring and control capabilities, ensuring optimal performance in all maritime conditions.

Marine automation and control systems play a crucial role in enhancing operational efficiency, safety, and reliability of vessels, while reducing the workload on crew members by automating routine tasks and providing comprehensive monitoring and control capabilities.

Our services include:

Integrated Control Systems:

Implementing centralized control systems that integrate various shipboard functions, such as propulsion, machinery, power management, and navigation into a unified system.

Power Management Systems:

Implementing advanced systems that efficiently manage the distribution of electrical power on the vessel, optimizing power generation, consumption, and load shedding.

Bridge Systems Integration:

Integrating bridge systems like navigation, communication, and radar into a centralized control system, enabling seamless information sharing and enhancing situational awareness for the crew.

Remote Monitoring and Control:

Enabling remote monitoring and control of vessel systems, allowing ship operators and engineers to access vital information and make adjustments from shore or other remote locations.

Data Acquisition and Analysis:

Collecting and analyzing data from various onboard sensors and systems to identify trends, optimize performance, and support decision-making processes for improved efficiency and cost- effectiveness.

Alarm and Monitoring Systems:

Installing systems that continuously monitor the ship’s vital parameters (temperature, pressure, levels, etc.) and provide real-time alerts and alarms in case of abnormal conditions or equipment failures

Automation of Machinery and Systems:

Automating various machinery and systems, such as engine control, ballast water management, cargo handling, and HVAC (Heating, Ventilation, and Air Conditioning), to improve efficiency, accuracy, and reduce human error.

Condition-based Maintenance:

Utilizing automation and sensor technology to implement condition-based maintenance strategies, where equipment health is continuously monitored, and maintenance tasks are scheduled based on actual condition rather than fixed intervals.

Safety Systems:

Implementing automation and control systems for safety-critical functions such as fire detection and suppression, emergency shutdown systems, and life-

saving equipment to enhance crew safety and mitigate risks.

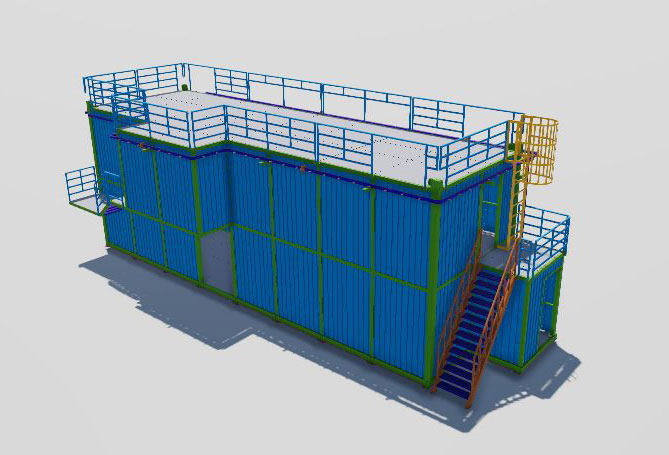

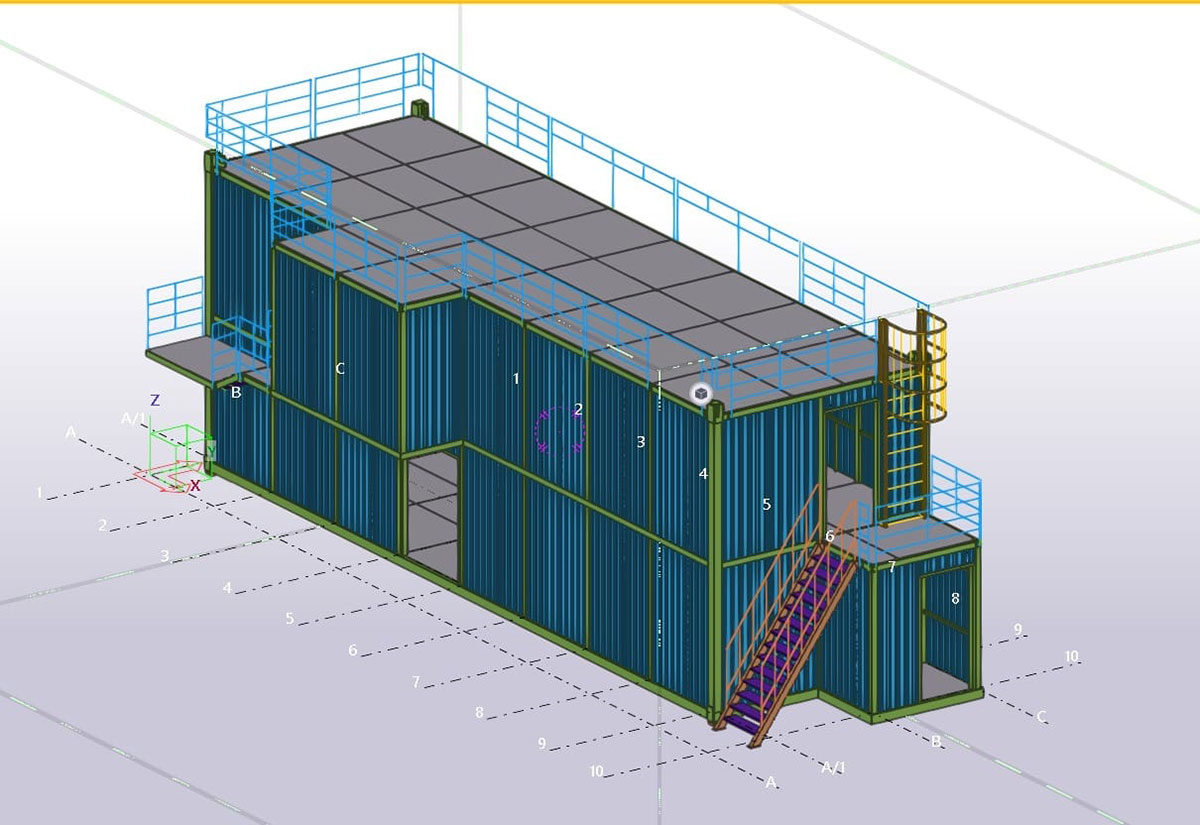

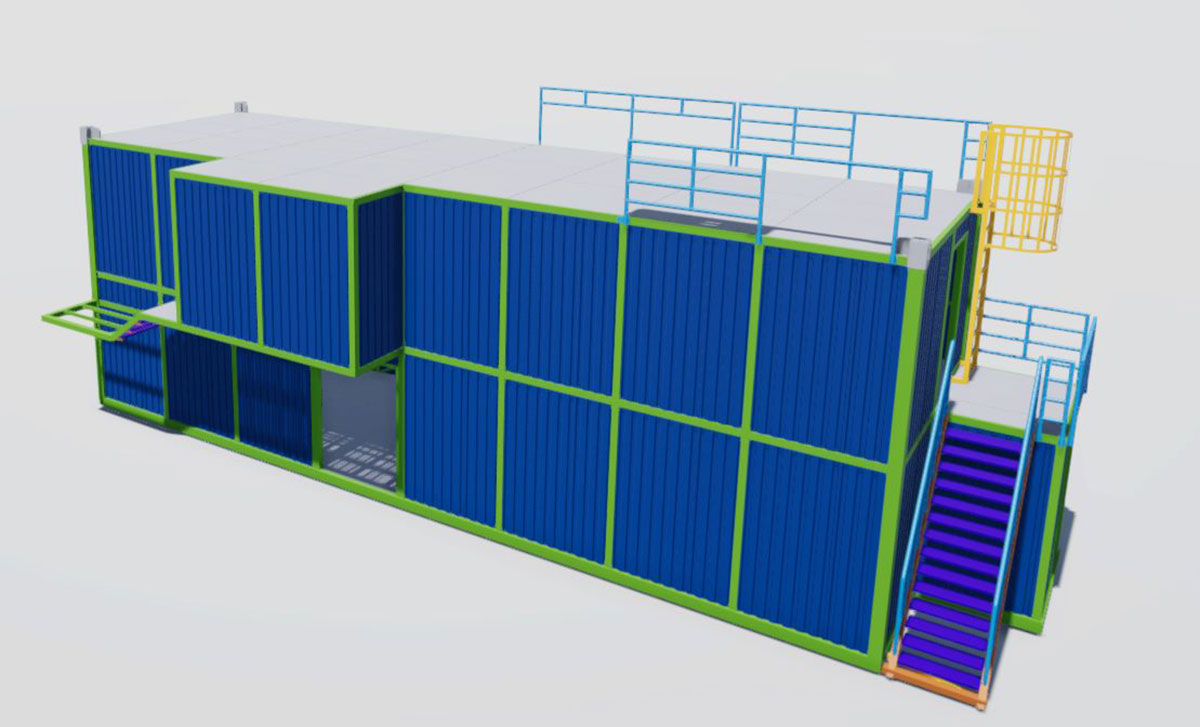

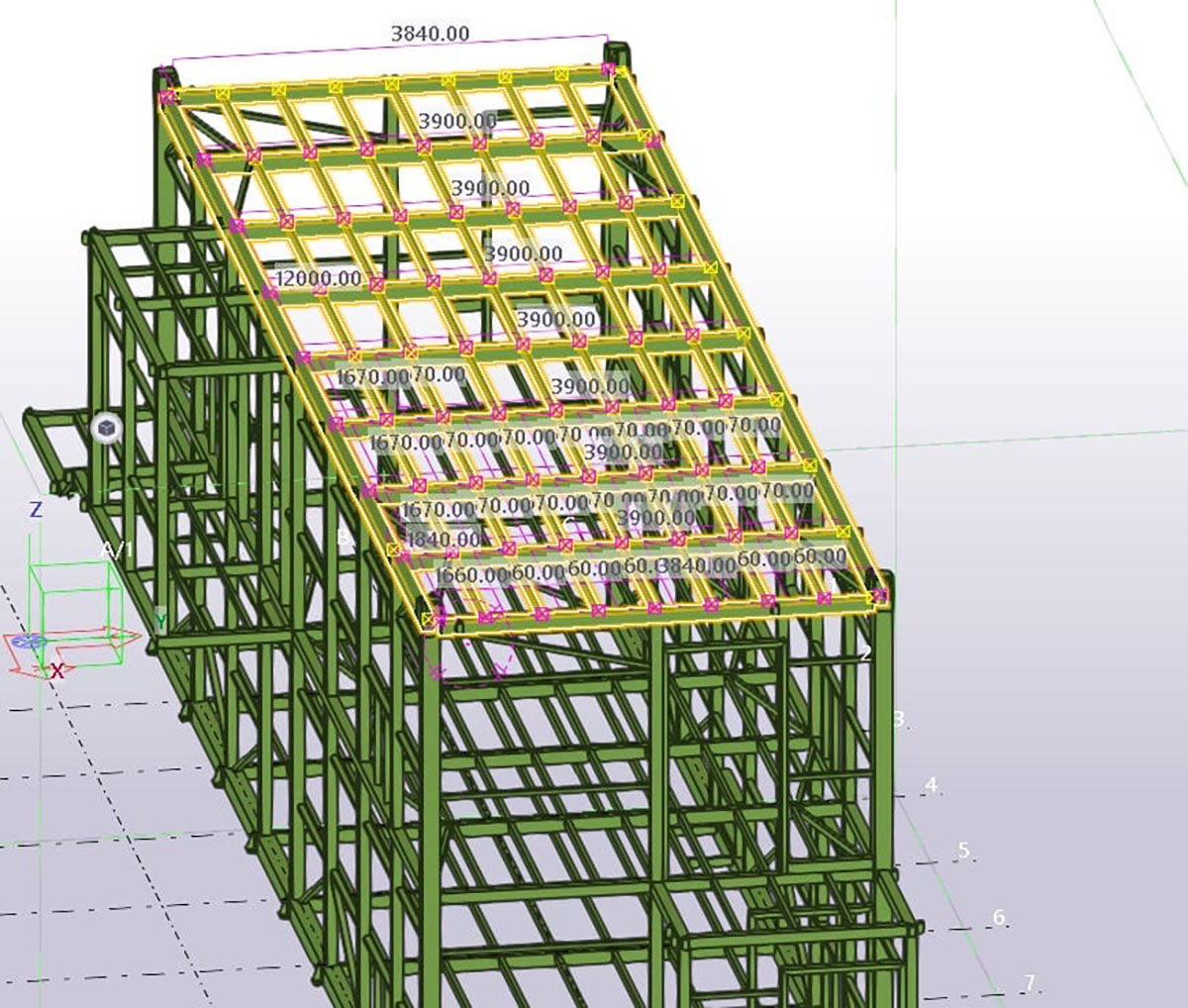

Our Projects

Explore our last projects

Qeydiyyatdan uğurla keçdiniz